Vintage Quick Change Rear End | A Brief History

Vintage Quick Change Rear End | A Brief History

It would be difficult to nail down exactly when the first quick change was developed. Early units ran the gamut from one-off, homemade pieces to production rears from people like “Cookie” Ledington (Cook’s Machine Works), Ted Halibrand, Pat Warren, and Jim Frankland. Most were based on a cast aluminum or magnesium center section that utilized early Ford carriers and axle housings. There were even some examples that incorporated a change gear housing that was welded directly to the back of a Ford banjo center section.

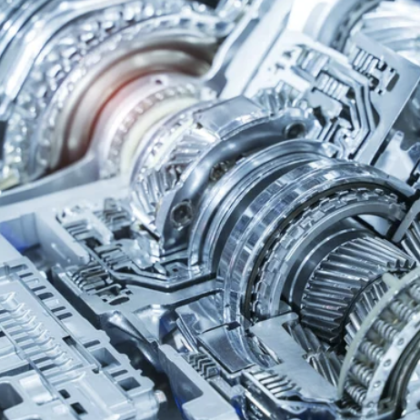

Early production quick changes were typically available in three different sizes. The smallest was known as a Model A or Midget rear, for Midgets and other lightweight racers; the mid-sized V8 rear was most used in roadsters and other mid-size and weight cars; and the Champ saw use in Sprints and other larger racecars. Today’s quick changes have been developed for far more specific applications, where the center section design is fundamentally different from one type of racecar to another. We’ll discuss those differences in a little more detail later, but first we’ll delve into the basic internal components universal to all quick changes.

English

English 中文

中文 繁體

繁體